This article was written by

Thomas Besley

Joining metals is never an easy task. Welding has been the conventional joining method for the past decade because it is strong, very strong.

But maybe you have a problem with welding. Or maybe you're having trouble finding skilled welders. Either way, you're looking for an alternative method of joining metal to metal.

Here at Forgeway we are adhesive specialists. We help people understand what they can and cannot do with glue.

The question of alternative connection methods for welding is a question that we answer regularly.

There are several alternatives. Adhesives are a solution that we will talk about in this article. But don't worry, the purpose of this article is not to sell you our adhesive product.

By the end of this article, we want you to understand what alternatives there are to welding. In this article, we'll discuss the alternatives so you can decide which connection method best suits your needs.

If you prefer to watch our video explaining this topic in more detail, you can watch Lauren discuss it below.

Why welding is a popular method of joining metal to metal

We should start by clarifying that you can also weld plastic, but this article is focused on metal to metal welding.

There are different types of welding. The three most common are MIG, TIG and stick welding. These are all different types of arc welding. Let me explain why they are so popularwithout going into further detail.

They are all relatively inexpensive, while offering highly durable compounds that are also extremely strong.

We should not underestimate the strength of a weld.As a general rule of thumb, a 1 inch weld can hold a maximum of 1 ton of force. It is one of the most robust connection methods.

The power combined with the speed at which it reaches handling strength makes it a no-brainer.

But there are problems with welding. In fact, you're probably experiencing them right now, which is why you're reading this article. We will discuss them next time.

Why is welding not always the best connection method?

The most prominent problem when using welding as a joining method is the scarcity of resources. Yes, there are other disadvantages to welding, but the biggest challenge is finding enough trained welders and welding equipment.

There is a serious shortage of highly trained welders. We may wonder why there is a shortage, but that is not what this article is about.

Ultimately, if you can find a highly qualified welder, make the most of it.

Even if you can find an experienced welder, there are still things you should pay attention to.

What has beenrecent changes in legislationregarding ventilation requirements during indoor welding.

In summary, welding fumes can be harmful. The HSE has introduced thisthese rulesto try to protect workers from these fumes.

Manufacturers usually install local exhaust ventilation (LEV) if they want to meet these requirements.

However, not everyone wants to install these LEVs as it is an expensive and time-consuming process. These LEVs cannot always meet the legal requirements.

The changed rules and the serious shortage of highly skilled workers pose major problems. They are the main reason for the shift to other methods of joining metals.

However, there are also other disadvantages to welding. Welding cannot connect different materials and creates a lot of heat. So much heat, in fact, that the metal can be damaged if not welded properly.

Global shortages are also affecting welding equipment, causing a shortage of welding tips.

What are alternative metal-to-metal joining methods?

There are two alternative joining methods for welding;mechanical fasteners and adhesives.

These two are often compared. We even wrote an articlediscuss which connection method is the best solution(Spoiler alert, the answer was "it depends").

It may seem biased from an adhesive specialist, but if someone knows the disadvantages as well as the strengths of adhesives; it's us.

There is a bit of history surrounding this topic. We can see the trends around the use of these joining methods on an industrial scale over the years.

Especially in the manufacturing industry, mechanical fasteners were the preferred mounting method. This lasted until the end of the 20th century, when a certain mechanical attachment became increasingly popular; Rivets.

These continued to rise in popularity until the benefits of welding became more widely recognized around 2010.

Welding then became the most popular method, as it still is today. As long as the metals were not different from each other, welding was normally always used to join them.

There currently appears to be a new shift. The problems with welding discussed above are causing the manufacturing industry to look elsewhere. They either go back to using mechanical fasteners, or try using glue (if they haven't used it before).

Mechanical fasteners

Mechanical fasteners are the method that most people know will work because they have probably used them before.

The advantages of mechanical fasteners:

- they require minimal surface preparation

- they are almost as fast as welding because they also have no curing time

- it is the only connection method that can be easily reversed

The disadvantages of mechanical fasteners:

- they are sensitive to point loads, which can cause fixation to fail over time

- they create dirt or "chips"

- they are a more expensive option than the other two methods

In short, mechanical fasteners can do the job. The manufacturing industry used them for years before they used welding, so they will work, but they are not perfect. Welding has overtaken its use for good reason.

Adhesives

Not everyone has used glue before. Especially in the manufacturing industry. Although the adhesives are significantly better than the existing method, the process of change is always scary.

Changing the connection method is never an easy task, we understand that.

Glues are an excellent option because:

- They are often the cheapest connection method

- They are the most effective method of joining newer, more advanced materials such as carbon fiber, composites and glass fiber reinforced plastic (GRP).

- In the right situation they can be as strong as welding

However, adhesives have some disadvantages:

- They usually require more surface preparation than the other methods

- They are the only method with a curing time

- They require knowledge of their use, but not as extensive as welding

So you know that mechanical fasteners will work to connect the metal. You also know that adhesives can provide a connection that is just as strong as welding.

If you want to explore 'Mechanical fasteners versus adhesivesdebate,download our checklist, which can help you find the best solution for you.

If gluing seems like a good welding alternative and you want to make sure you're using the right adhesive for your metal, read on.

Or you can take the 45-second quiz below to help you find the perfect adhesive for your application.

Can you use an adhesive instead of welding for a metal-to-metal connection?

Yes, you can use adhesives instead of welding to connect metal to metal. Adhesives can make a joint as strong as welding. Although there are of course caveats.

If you need a reliable and durable connection (of course you do), consider the joint design.

A conventional weld will always provide higher strength square millimeters than gluing.

It can mean several things if you want to use glue instead of welding. But the most important thing to do is make sure that the surface area of the joint is large enough for the adhesive to bond effectively.

Some may know this as the thickness of the connecting line, but if you didn't know it before, you know it now. We normally recommend a glue line thickness of 1mm-2mm.

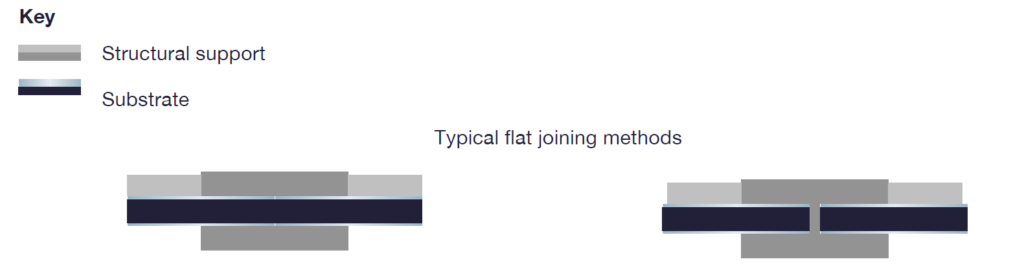

Certain compounds do not provide sufficient surface area for effective bonding with adhesives. In these cases you need structural support for the connection to achieve the same strength as gluing.

So ultimately the answer is yes, you can use glue instead of welding. But you will need to take these considerations into account to ensure that the assembly achieves sufficient strength.

If you're ever concerned about the strength of the adhesive, don't take any chances. Contact the supplier orcontact an expertwhich will help you decide how to use your glue.

What is the best connection method for me?

The answer to this question depends a lot on what you are looking for in the joint. We understand that you may be having trouble welding, and we can probably guess why.

So if you are looking for an alternative joining solution to join metal to metal, don't worry. There are other connection options than just welding.

Because we are the adhesive specialists here at Forgeway, we can tell you what is and is not allowed with glue.

However,if you can find a skilled welder, you will have the necessary extraction and a robust joining method you can rely on; welding is the best option for you.

If not, you can use mechanical fasteners or glues.

Mechanical fasteners provide a quick and easy connection method that is easy to remove if necessary. But they may not be strong enough and will likely weaken over time.

Adhesives provide an easy and inexpensive method of joining metal to metal. They are also significantly safer than welding. But they can be difficult to use and may require structural support.

Your situation is probably different, andmaybe you need help from an expertto assess your specific situation.

To read more about joint design and proper structural support methods,Chapter 6 of our eBook provides more information. Or download the full e-book via the link below.